1.The honing process overview

Honing machines is a commonly used finishing process, the honing process is a special form of grinding, and finishing in a highly efficient machining method.This process can not only remove larger machining allowance, and is a kind of parts size accuracy and geometric accuracy and surface roughness of effective processing method, can obtain high dimensional accuracy, high shape accuracy and low roughness (up to Ra 0.05), and produces the desired oil-bearing crosshatch pattern., is widely applied in mechanical manufacturing industry.

2.The classification of honing machine

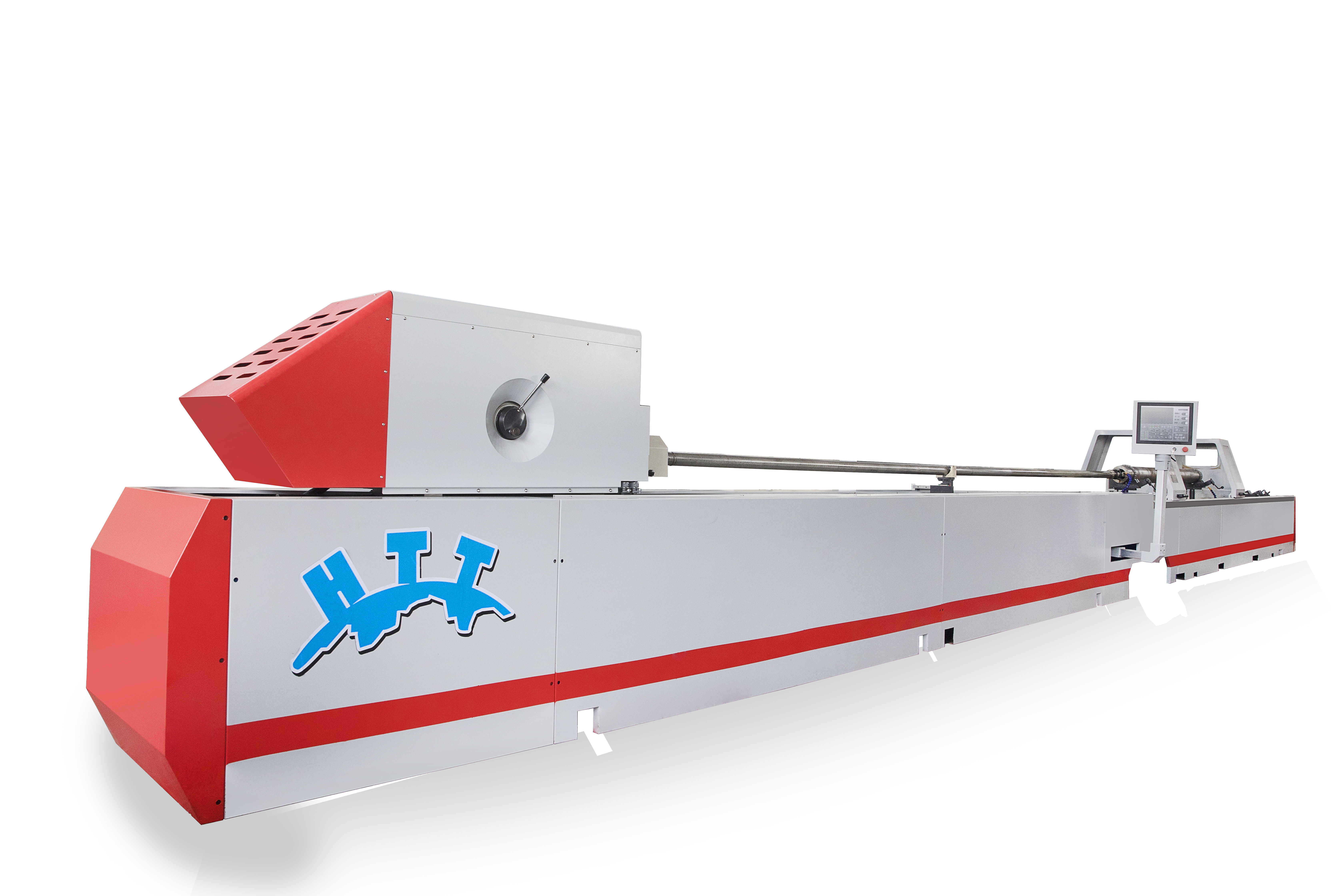

The types of deep hole honing machine: plane honing machine, cylindrical honing toolings, inner hole honing machine, etc. Honing machine form is divided into two kinds, one of type is vertical honing machine, the other one is horizontal honing machine. At present, honing machine for the inner hole is widely used in the world.

3. The honing process characteristics and application scope

1) honing can obtain higher dimensional accuracy and shape accuracy, and machining precision to IT7 ~ IT6 ,hole roundness and cylindricity can be controlled within the range of 3 ~ 5 microns, honing process cannot improve the positional accuracy of the bore.

2) Honing can obtain high surface quality and surface roughness, Ra is 0.2 ~ 0.025 microns.

3) Compared with the grinding speed, circular velocity of honing tool is not high, but because of honing stone and the workpiece contact area is large, Stroke speed is relatively high, so the honing still have higher productivity.

Honing in the large number of mass production is widely used in the engine cylinder hole and all kinds of hydraulic equipment for precision hole processing, bore size range for dia. 5 ~ 500 ㎜ or larger, and deep processing of length to diameter ratio is more than 10.

Vertical CNC honing machine

Vertical honing machine, its structure of honing axis is perpendicular to the work surface. Can be done under single-axial and double-axial and multi-axial mode, honing location can be made into two or more; Spindle arrangement, can be round or straight line type. Vertical honing machine can increase the online measurement and full closed loop control, ensure the machining parts size consistency; the structure for Vertical honing machine is conducive to rapid cooling fluid away after honing cutting particles, completely avoid the weight of the factors for the workpiece itself (or spindle) during the honing. Adopt CNC servo control, high machining accuracy, the product’s good consistency, and many other advantages. But the vertical honing machine is limited by a workshop space and itself covers an area of small, are unlikely to hone long workpieces, such as oil cylinder.

Technical Data

| Type | HM2000 | HM3000 | HM4000 | HM5000 | HM6000 | HM8000 | HM10000 |

| Max. stroke (mm) | 2000 | 3000 | 4000 | 5000 | 6000 | 8000 | 10000 |

| Diameter range (mm) | φ50-400 mm (special range: φ25-1000mm) |

| Cooling tank (L) | 500 | 500 | 500 | 1000 | 1000 | 1000 | 1000 |

| Machine length (mm) | 6200 | 8200 | 10200 | 12700 | 14700 | 18700 | 22700 |

| Machine width (mm) | 1000 | 1000 | 1000 | 1200 | 1200 | 1200 | 1500 |

| Height of machine (mm) | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 |

| Weight (kg) | 2600 | 3000 | 3400 | 4200 | 4600 | 5400 | 6200 |