- Home

- About HTT

- Jobshop

- Machines

- Deep Hole Drilling Machine Engine Valve

- Deep Hole Drilling Machine Connection Rod

- Deep Hole Drilling Machine Medical Parts

- Deep Hole Drilling Machine Fuel Injection Parts

- Deep Hole Drilling Machine Compressor Crankshaft

- Deep Hole Drilling Machine Gear Shaft

- Deep Hole Drilling Machine Cam Shaft

- Deep Hole Drilling Machine Gun Barrels

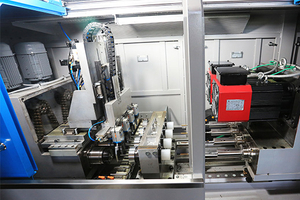

- HTT Gun Drilling Machine

- KBR Deep Hole Drilling Mould Making

- KB Deep Hole Drilling Machine for Mold

- BTA Deep Hole Boring Machine

- Knee-type Deep Hole Drilling Machine

- Ring Die Deep Hole Drilling Machine

- Deep Hole Drilling Machine for Honeycomb Ceramic Substrate Mold

- Tool Accessories-Gundrill Grinding Machine

- Tool Accessories-Drill Bushing

- Horizontal Pellet Die Deep Hole Drilling Machine

- Honing Products

- Job Shop

- Accessories

- Machines

- Application

- Process

- Machine Photo

- Service

- Online Shop

- News

- Recruitment

- Contact Us